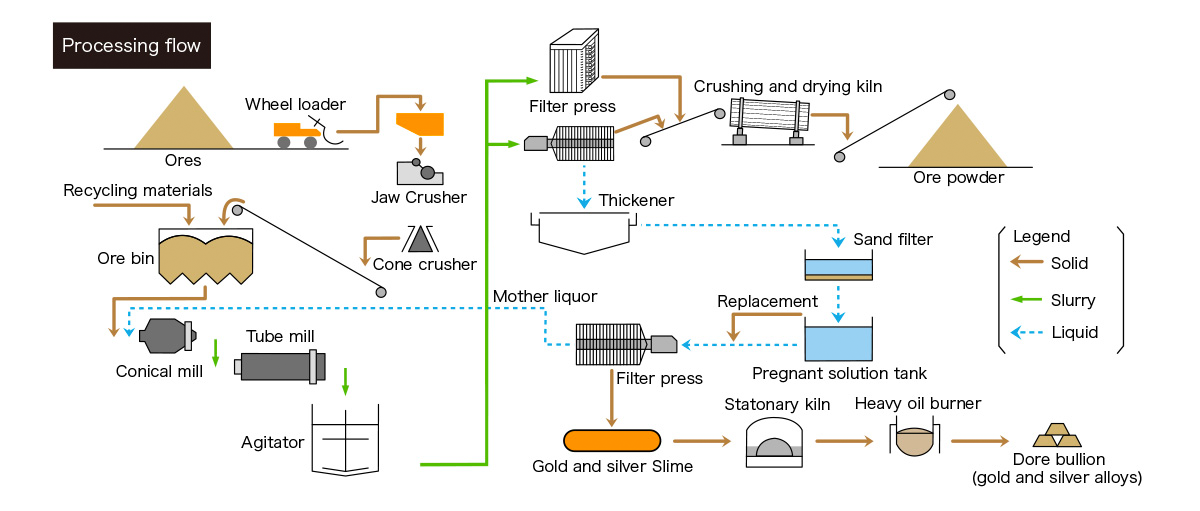

Casting of dore bullion (gold and silver alloys) ingots

Extracting gold and silver from ores. Selling ingots to the Takehara Smelter. Selling ore powder to domestic copper smelters.

At the only Whole-sliming cyanidation smelter in Japan, we extract gold and silver from gold ores through energy-efficient, fully mechanized Processes.

First, a crusher breaks gold ore into pieces, a conical mill grinds it until it is slimy, then a Processing liquid is added to dissolve andextract gold and silver.

The extract is filtered by a sand filter tank to become a cleaned liguid. Gold and silver contained in the liguid are collected by a displacement reaction process as gold-and silver-bearing slimes.

The collected slimes are turned into dore bullion (gold and silver alloys) in a refining process to become recognizable metals for the first time.

1. Ores

2. Conical mill

3. Tube mill

4. Agitator

5. Filter press

6.Larox filter

7. Crushing and drying kiln

8. Thickener

9. Pregnant solution tank

10. Gold and silver Slime

11. Heavy oil burner

12. Dore bullion (gold and silver alloys)

Processing flow